Front Seat Tacking Strips (Pair)

Suitable Models: TR3A, TR4

$47.92 exc. VAT UK Customers ONLY - VAT (20%) will be calculated at checkout.

For many Seat Covers, clips and glue were the standard methods. However, some seat frames allow for tacking strips – which can make the fitment process a lot more straightforward.

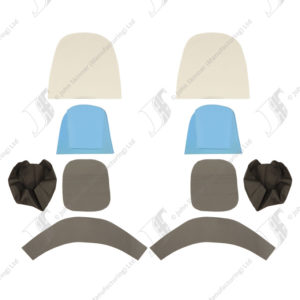

The introduction of the TR3A, as it was unofficially known, saw changes to the seat assembly units. Both the seat framework and the associated seat covers were updated to a narrower style “egg” shaped backrest squab. This frame allows for the use of tacking strips to be used in the fitment process of the Seat Covers to the framework. These tacking strips are riveted to the seat frames in specific areas, and you can then use tacks to attach the material of the backrest squab cover to the framework. Tacking seat skins in place offers a lot more flexibility as you can easily move and change the positions of the tacks allowing for the tension to be applied in different areas during the fitment process. These tacking strips are suitable for all TR3″A” and TR3B models, as well as the first period of mass production of the radically overhauled, Giovanni Michelotti designed, TR4 model, first introduced during 1961. The use of the “TR3A” seat framework, and the associated tacking strips, was further prolonged into the brief period of manufacture of the rarely seen vertical-pleat style covers (JSM refer to these as “TR4A Early – 30b”) that were also fitted to the TR3A framework, before the switch to the square-backed “Late” style seats commonly used in the TR4s.

These tacking strip kits are cut on our in-house CNC machine and include pre-drilled pilot holes for the split rivets, as well as the rivets themselves. Note that the tacking strips are only used for the reupholstery of the backrest covers; as the cushion covers are trimmed to the spring unit using hog-rings.

DETAILS

- Supplied in 2.55mm hardboard.

- Pre-cut to the different shapes required to position around the metal framework.

- Pre-drilled pilot holes for the split rivets are also included.

- 26 x Silver Rivets included measuring approximately 5/8″ in length.

Why JSM?

- Made in England, only 50 miles away from the original production line.

- Our kits are manufactured using the same methods and templates that we have used to great success for 40+ years.

- Access to help and advice when it comes time to fit the covers – we have been making and fitting these same covers for a long time – we know all the tricks, and we are more than happy to assist you or your trimmer should you get stuck.

| Unit of Sale | |

|---|---|

| Lead Time (*approx.) | |

| Number of Pieces | |

| Suitable Models | |

| Year of Manufacture | |

| Chassis Number Range | TS22014 – TS60000, TS60001 – TS82347, TCF1 – TCF2804, TSF1 – TSF530, CT1 – CT40304 |

| Misc. Information | British Leyland, Carburettor, Coventry, Soft Top, Giovanni Michelotti, Long Door, Short Door, Small Mouth, Standard Motors, Triumph, Wide Mouth |

| Illustration Ref. |

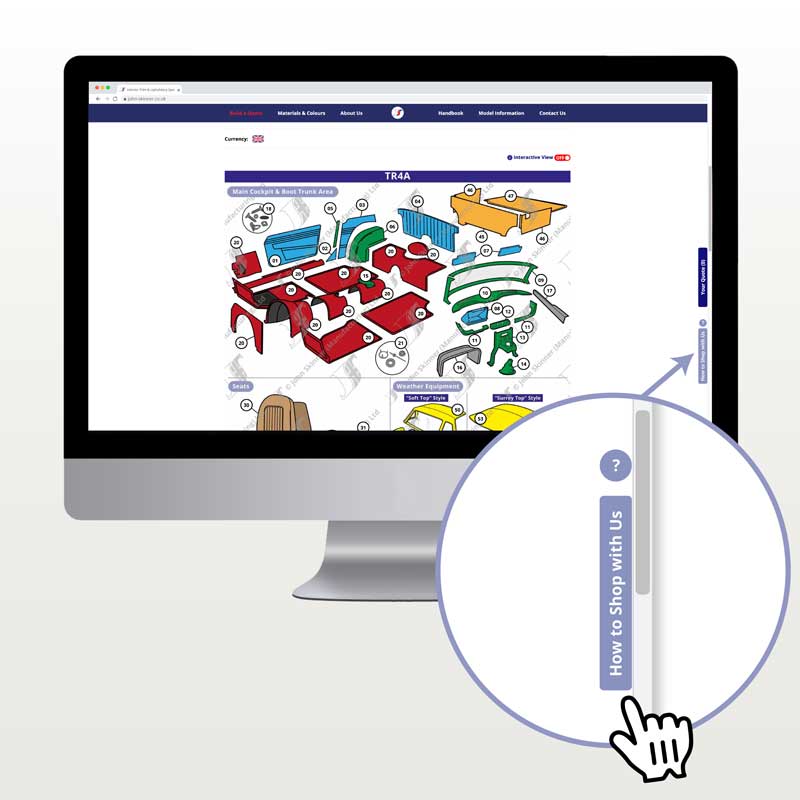

Due to the range of products we offer, and our worldwide customer base, we can only calculate an accurate shipping cost once Your Enquiry/Quote has been received by Jonathon. As there is no payment required at this stage – use our Quote Builder in full confidence, with zero commitment to purchase – and send us your Quotation request for your interior trim requirements; and we will get in touch directly with you with an updated Quote, which will include the shipment costs.

In the meantime, basic guideline shipping costs are outlined below.

(For all non-UK shipments – the final price per box depends on the size of the box – which is dictated by the items in your final selection)

UK: £10.50 – £30 per box

Europe & European Union: £20 – £150 per box

North America & Canada: £28.50 – £160 per box

Rest of World: £50.00 – £400 per box

Generally speaking, a complete car interior kit (Trim Panels, Carpets, Seat Covers, Boot/Trunk area, Soft Top Hoods etc) normally requires 2 x FULL Size Boxes, with some cars needing slightly less, and some slightly more.

Please note that these prices are exclusive of VAT (UK Customers ONLY) and any additional customs or handling charges that may be incurred during shipping. These prices are given as an approximation only.

For further information about shipping, and to learn more about how our shipping costs are calculated, please read our Shipping and Delivery guide.

🇪🇺 EU Shipments / Brexit 🇪🇺

As of January 2021, the UK is no longer part of the European Union (EU). As a result, several changes have been implemented which affects how EU based customers now purchase products from the UK.

It is not as problematic and complicated as people say. John Skinner Ltd sends hundreds of shipments to the EU; and rarely do we encounter any issues at all; and this is due to us working closely with our shipping agents to offer two choices that help to simplify the process for you.

You now have 2 Options you can choose from for shipping John Skinner products to the EU:

============

Option 1: Standard International Shipping

This is the ‘standard’ method of purchasing items from the UK, since the UK left the EU (‘Brexit’).

You will pay John Skinner Ltd for 1) the parts ordered, and 2) the shipping cost to ship from the UK to your address.

You will NOT be charged UK VAT (20% Tax). (Before Brexit, you would have been charged UK VAT @ 20%).

Once your parts ship, you will be contacted directly by our shipping agent (normally DHL), who will request payment from you for 1) Your Local Country Tax based on the value of the John Skinner Invoice, 2) a small admin fee (normally around €15). Once this is paid, your goods are released from customs and delivered to your address.

You will NOT be charged any Duties/Tariffs. All the parts we supply are made by John Skinner Ltd in the UK, and we provide all the correct paperwork & documentation and sign declarations to ensure that no Duties/Tariffs apply to our goods. (This is often the part that most people get confused by with Brexit – they assume that anything they buy from the UK incurs Duties/Tariff charges – our products are 0% Duty/Tariff rated).

Note that this shipping option is the default choice offered when Jonathon is raising your initial Quote; if you wish to discuss the second option (see below) – then just mention this to Jonathon once he has made direct contact with you about your enquiry.

============

Option 2: Prepaid Duties & Taxes *** VERY POPULAR OPTION ***

To simplify the purchasing process, you can choose our Prepaid Duties & Taxes option.

This process is becoming the most popular option for our EU customers as it makes everything very simple and straightforward, akin to how it was before the UK left the EU.

We will calculate & include all applicable import duties, taxes, and customs fees in your order total – and everything is paid up front to John Skinner Ltd.

Once the parts are ready and are shipped – you will NOT pay any additional costs, or have to do anything more – your order will be delivered to your address as normal. Our shipping agent (normally DHL) pays the Local Country Tax on behalf of John Skinner Ltd and they Invoice us for this later. This ensures that you won’t face any unexpected charges upon delivery, and your order will clear customs smoothly and quickly.

You can enjoy a more streamlined shopping experience with this option; like Brexit never even happened.

If you are interested in this option, please let Jonathon know once he has contacted you directly with your updated Quote via email; and he can update the Quote accordingly to reflect this choice.