We’ve embraced technology within a traditional industry to enable us to deliver exceptional interior trim kits.

Our position in the industry has seen an increased demand for our products. With technology, we have been able to increase capacity in our workshop and bring a consistency to our production line that could never have been achieved by hand. Whether it’s a door panel or a carpet kit, a glove box or a seat cover, our machines cut with millimetre accuracy every time.

Read more about the machinery and technology that’s helping us craft our interior trim kits.

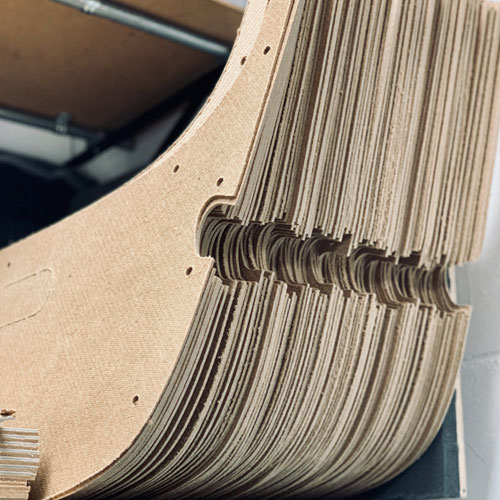

CNC Router

For millimetre precision across our panelling items, we cut all our backing materials – hardboard, millboard & black grain board – on a dedicated CNC machine. We pre-cut all relevant fixing holes for attaching the panels to the car, as well as guide “pilot” holes for other elements required such as door handles, window winders, and fixing brackets for associated panels or parts.

Our digital patterns are taken from the same templates on which the company was founded and we have worked to improve them over the years to ensure the best quality of fit across cars that originated from an inconsistent factory production line.

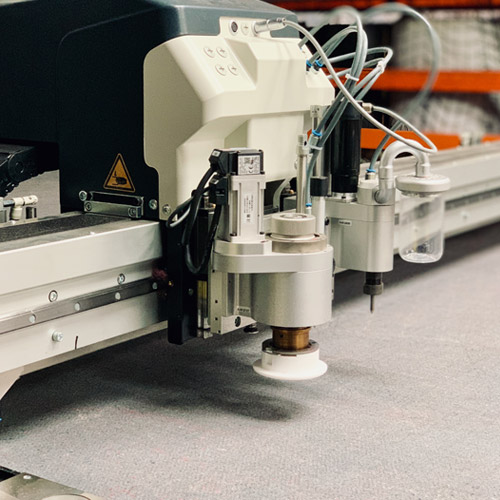

Digital Cutter

Our leathers, vinyls, carpets and all other soft materials are cut on our innovative digital cutter. With this machine, we can cut with speed and millimetre accuracy whilst eliminating the mistakes and discrepancies that can result from cutting these materials by hand. Our Digital Cutter can precisely position notches along sewn edges, providing our Sewing Department with accurate pieces from which to work and ensuring that parts are assembled correctly and consistently each time.

Skiving Machine

We have recently invested in a Leather Skiving Machine. This works by shaving off the back of the leather, thinning it down to a required thickness without compromising its core strength. Perfect for Leather Door Top Cappings or Centre Console areas, skived leather is pliable and gives a neater finish where normal thickness leather would prove cumbersome and tricky to work with. With our knowledge of these cars, we supply relevant parts of a trim kit skived as standard and at no extra cost.

You can learn more about skiving in our Handbook post – What is Leather Skiving?

HF Welder

For many years now, we have had an on-site a High-Frequency (HF) Welder machine. This machine is used to emboss patterns onto certain car panels and seats, as per original specification. Examples of this can be found on the Austin Healey BJ8 Quarter Panels and Seat Panels; as well as many of the Triumph TR4 to TR6 models, and some of the Jaguar MK2 and later Saloon models.

We are one of the only companies in the world to have the original template designs for these patterns, and offer these as standard in our kits.

Read more about our original specification weld tooling in Our Tooling.

Sewing Machines

Our sewn items are made on our traditional industrial standard Singer and Seiko sewing machines – some of which date back from the 1940’s. These machines are robust and cope with the heavy duty materials we feed through them. Despite investing in such modern technology in other areas of our production line, we feel incredibly privileged to still have these beautiful and historic machines as an integral part of our workshop.