Your Quote

Our carpet kits are renowned worldwide for their excellent fit and finish.

Crafted from highest quality materials, cut with speed and accuracy on our digital CNC machine and assembled by our skilled machinists, our carpet kits are simply exceptional.

Over the years, we have adapted our carpet kits to allow for greater flexibility in fitting. We have updated production-line patterns without compromising originality and our kits are designed to accommodate modern-day soundproofing technology should your restoration demand.

The nostalgic part? Our carpet kits are bound and sewn with the Seiko and Singer sewing machine models that would have been seen on the original factory production lines.

Read more about the key features of our carpet kits below.

Expert Knowledge of Original Materials

When it comes to car flooring, we really know our stuff. We have developed all our Carpet Kits with a highly informed level of knowledge which not only informs good fit, but also accurate material allocation throughout the car cockpit. Whilst some models simply have carpet running through the whole flooring area (such as the Triumph TRs), other models (such as the Jaguar E-Types) feature carpet, hardura, moquette and vinyl materials in a variety of combinations depending on the year of manufacture. Austin Healey’s were unique too in their use of a ribbed flooring material called Armacord which was complemented by a ribbed effect carpet known as Karvel (and before you ask, yes, we do know which direction the ribs run in the car according to model!)

Our extensive knowledge in Jaguar, Austin Healey, MGA and Triumph flooring has informed the options we offer in our Material Library. Flooring materials have been sourced according to original specifications and colour options are varied enough to satisfy all interpretations of original schemes.

We advise our customers on their flooring material choices based on the look and feel of their restorations, in addition to what would have originally left factory production lines and our in-house Primary & Secondary colour system helps guide colour choices to ensure there is a cohesive look between flooring, panels and seats. We can also suggest where material upgrades / adaptations can be made from original trim without compromising the feel of authenticity.

Wool

A truly beautiful material, our Wool carpet is of exceptional quality; luxurious to the touch with a deep, springy pile and befitting of high-end restorations.

The rubber backing provides flexibility and malleability in fitting whilst also holding the carpet firmly in place once in the car. The dense weave also means that the fibres won’t spread when the carpet is shaped over bodywork curvature.

Our Wool carpet is, quite literally, fit for a King – we have supplied the wool carpet to the Jaguar Daimler Princess belonging to the King of Sweden, Carl XVI Gustaf. You can read more about this in Our Notable Restorations.

Our wool carpets are available in a range of around 20 colours.

Karvel

Karvel carpet has a ribbed effect to the surface and is finished with a hessian backing.

It’s ribbed weave makes it a sturdy and robust material, suitable for day-to-day automotive use with a short and stiff pile.

The linear ribbing gives a distinctive look, and the carpet was most commonly seen throughout Austin Healey and MGA interiors.

Karvel is available in 4 colours – Black, Blue, Red and Grey.

Nylon

Our tufted nylon is a man-made material that offers an affordable option for those not wanting to go to the expense of wool. With a deep pile of 100% polypropylene fibres and a rubber backing, it is flexible, durable and hard wearing.

Ideal for restorations working to a budget, Nylon carpet provides a practical solution for Boot/Trunk and Cockpit areas.

Hardura

Hardura is a heavy jute-backed flooring material, most commonly seen throughout the Jaguar range of cars across Rear Floor, Bulkhead, A-Post, Under Dash and Boot/Trunk areas.

It is a plastic coated material with an embossed grain effect to its surface, is very hardwearing and carries sound-proofing benefits thanks to its felt backing.

Armacord

Similar to Hardura, Armacord is the same plastic coated material but with a ribbed effect embossed on top of the surface grain.

Jute-backed, heavy and hardwearing, Armacord was most commonly seen across the Austin Healey range of cars and used for Rear Deck, Rear Floor and Boot/Trunk areas.

Complete Floor Coverage

Our carpet kits are made of a number of pieces with bound and unbound edges.

Bound edges are cut-to-fit and are ‘on-show’ when in position, whereas un-bound edges are often hidden under adjacent parts. This gives a cohesive visual ‘blend’ to the carpet pieces as they pass from piece to piece without gaps between them. This enables our carpet kits to completely cover the floor area of the car, hiding any unsightly bodywork and covering over draughty gaps.

Where possible, we have added additional length to our original specification patterns along un-bound edges to give our customers more carpet to work with and greater flexibility when trimming.

For instance, we have made our gearbox patterns wider so that they can be anchored in place by the adjacent floor carpets that sit either side; our sill carpets are wider than required so that front and rear floor carpets can sit neatly against the edge of the sill, and we have extended edges of our carpets that meet with our panel work so that they merge smoothly from one part of the car to another.

Not only does this oversizing allow for flexibility in fitting, it also allows for the natural movement of the carpet when the car is in use, giving an overall more secure and safe carpet installation for the driver and passengers. With our extended edges, rear floors can slip slightly from the sills, or shuffling feet can catch the edges of floor carpets, without exposing any bodywork.

OEM Specification Leathercloth Binding

For bound edges on our Carpet and Boot/Trunk kits, we use leathercloth binding as per original specification.

Leathercloth has many qualities that make it suitable for carpet binding. With a woven cotton backing, its lack of stretch helps our carpets maintain their shape both during manufacture and once fitted in the car; it doesn’t snag; and it may sound obvious, but its overall specification means that it simply looks good and is fit for purpose.

We most commonly bind our carpets around their external edges and around cut-into areas positioned on the carpet to accommodate fixed elements of the car, such as throttle pedals.

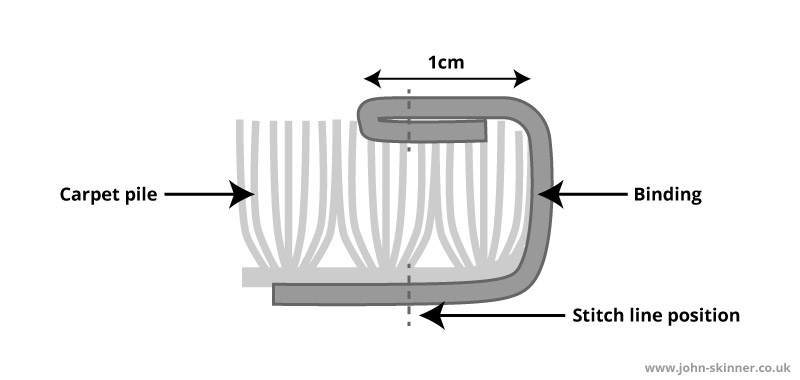

We attach our binding to our carpets with our 1940’s Singer sewing machine. This loops the binding round the edge of the carpet, giving a neat 1cm binding finish to the surface and creating a ‘e’ style cross section construction. This is shown in more detail in the below image.

Our leathercloth binding is available in a range of 23 colours which complement our Wool, Nylon and Karvel carpet ranges. You can view all our Leathercloth bindings here.

Designed for use with Underfelt

Our carpet kits have been created to work in conjunction with our Underfelt Soundproofing Kits.

The fitment of a carpet kit is largely determined by the thickness of the Underfelt below. In addition to providing heat and sound resistance, the thickness of our Underfelt Soundproofing Kits ensures that our carpet kits fit well, look good and give added comfort underfoot once installed within the car.

Whilst there are now much more sophisticated soundproofing materials available on the market that utilise modern-day sound and heat resistant technology – and we would recommend you use these should your restoration budget allow – they’re very thin and are not suitable for use with our carpet kits alone. We always recommend installing our Underfelt Soundproofing Kits on-top of any modern-day soundproofing before fitting our carpet kits.

A few more details that really make us proud of our Carpet Kits…

Traditional Machinery

Our skilled machinists bind all our carpet kits with our 1940’s Singer binding machine. This machine is a treasured piece in our workshop and will be a similar model to those used on original factory production lines.

Choice of Edging Colours

Choose from our selection of leathercloth binding colours for your carpet edging, available in 23 colours to match our Wool, Karvel & Nylon carpet ranges.

Modern-day Soundproofing

Our Underfelt Soundproofing Kits are available in Dynamat and Dodo Mat fabrications that use modern day technology for heat and sound resistance. These are designed to be used in conjunction with our original specification 6mm jute felt kits.

- Categories: Misc