Convertible Soft Top Hood

Suitable Models: TR4A

$971.68 – $1,365.84 exc. VAT UK Customers ONLY - VAT (20%) will be calculated at checkout.

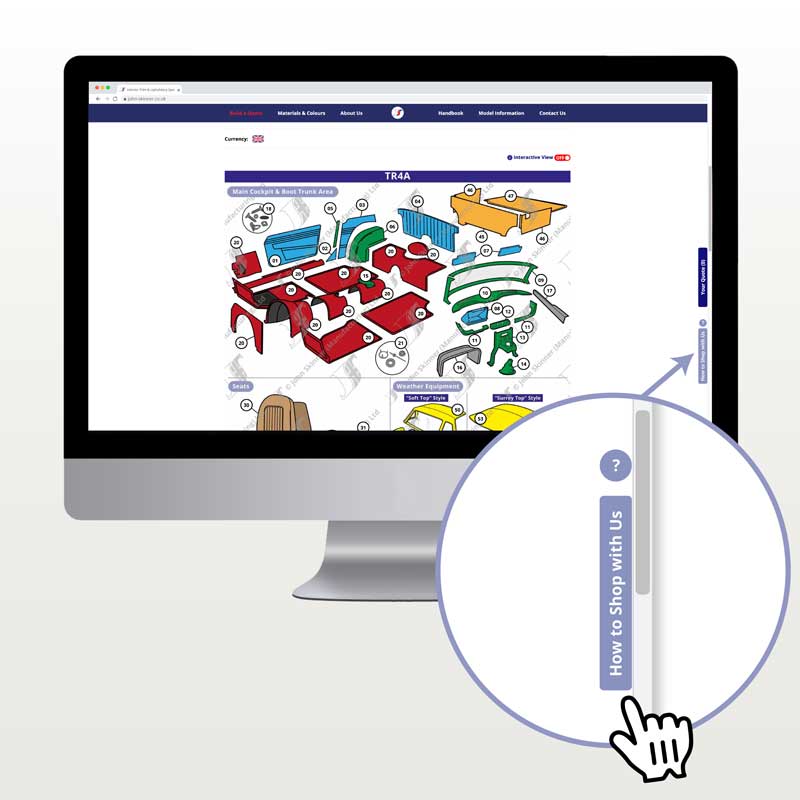

These days it is rare to see a convertible soft top hood in use…but just in case you get caught out by a sudden rainy down-pour – make sure you have a Hood that will keep you and your interior dry, whilst still looking as great as the day the car left the factory. Available in a limited variety of materials and colours. See below for more product details and information and FAQs.

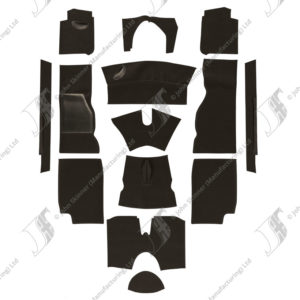

The TR4 “IRS”, with the introduction of the Independent Rear Suspension (IRS), was unofficially dubbed the TR4″A”. To glance at, the Soft Top Convertible Hood looked similar between the two models – but upon closer inspection, there are various areas of evolution. The Convertible Hood on the earlier TR4 model featured a unique, and quickly discontinued method for stowing the retracted down metalwork of the hood frame behind the rear squab bulkhead cover. The theory of this worked, but in practice, the process was a little clumsy and time consuming due to having to remove the actual material cover prior to folding the metalwork away. As a result, Triumph updated this process on the TR4A models and all other proceeding TR models after that. They designed a Hood that remained attached to the Hood Frame metal sticks even during the folding away process, thus eliminating the need to physically remove the cover before this process. Once folded down around the rear deck area of the car a sewn material Hood Frame “Envelope” Cover, similar to the ones used on the earlier TR2-3B models, was used to cover over the Convertible Hood and Framework. Due to the fact that the Hood and Framework were mounted together and remained as a unit when folded down at the rear of the car, the combination of the two was a lot bulkier in size when compared to the earlier versions. As a result, Triumph flattened the top of the rear wheel arches on the interior of the car to allow extra room for this bulkier Hood. This led to the changes to the interior upholstery and panels used for the Quarter Panels and Bulkheads. The Soft Top still included the 3 rear window set up as per the previous TR models; and these were then HF/RF welded into position. There was a significant update to the front of the Hood and the method used to attach this to the windscreen frame. The updated TR4A Hood was made longer with excess unfinished material on the front edge, allowing for the header rail to be wrapped with this material – with the three-piece metal channel and rubber seal then attached to this hood frame metalwork. Using clamps/toggles located inside the car near the centre sunvisor mounting bracket – the hood frame was attached to the top edge of windscreen frame. The rear edge of the Hood also featured some excess material on the underside which was wrapped around a metal assembly bar which was then bolted to the rear deck bodywork of the car, with male lift-a-dot “pegs” left exposed for attaching the Hood Frame or Tonneau Cover. Akin to the TR4 version – an additional left to right flap was sewn in the middle of the underside of the Soft Top with studs inserted – which was used to wrap around the horizontal Hood Frame rod above the drivers head, and secure in place. The side gutter channels on the left and right edges were also updated, but followed the same concept and served the same purpose.

The majority of Triumph TRs left the factory with PVC Hooding – this is effectively a pvc vinyl plastic material with a waterproof membrane, and featuring a grain in the surface of the material to imitate vinyl/leather. The actual material used was Everflex (known as “British Everflex”) – which was an ICI trade name for PVC Hooding (think “sticky tape” and “sellotape”!). Some special-order models may have left with Deluxe Mohair Canvas. The clear plastic windows at the back were made in a Vybak plastic. The TR4 to TR6 Soft Tops all seem to have been available in either White, possibly Off-White, or Black Everflex from the factory production line.

Here at John Skinners, we have patterns and templates for the Triumph TR4A Soft Top Hood, all designed using the factory designs and donor cars – of which John has owned a few himself. These same patterns and manufacturing processes have all been used consistently for 40 years – to good effect with our kits winning many awards the world over. However, please be under no illusions – the Weather Equipment elements (Soft Top Hood and Tonneau Covers) are tricky to fit, even for an experienced trimmer. We strongly urge you and your professional trimmer to contact us for directions on the best methods for fitting these items, as some fitment processes are irreversible. These parts are not meant to be easy to fit – that’s why when they are done correctly, the material is as tightly pulled and tort as a drum. Remember that a well-made kit still requires skill and attention to detail in order to fit it successfully, but a badly made kit will never yield good results. Don’t leave this to chance – use a John Skinner kits, and ensure you fully understand the process of fitting before you start.

We can offer these kits in the original PVC “Everflex” Hooding, or in the more premium Deluxe Mohair Canvas material, in a variety of colours to suit both the “as original” enthusiasts, or those after a more custom finish to their restoration.

You may wish to consider our Tonneau Cover to complete the external “Weather Equipment” set.

DETAILS

- Available in automotive-grade PVC Hooding (Everflex) or Deluxe Mohair Canvas.

- Three plastic “Vybak” windows, High-Frequency welded in place as original for these models (only for PVC versions, Mohair versions are sewn).

- Edged with the traditional “e” cross-section binding edge finish – where the material edge trim material tucks round on itself meaning no raw material backing is exposed.

- Includes excess material on the front edge for re-trimming of header rail during the fitment process.

- All “Female” fixings are included. These are supplied loose, not pre-inserted – see FAQs for more information.

Why JSM?

- Made in England, only 50 miles away from the original production line.

- We source only the highest quality raw materials to manufacture our products – demonstrated by using on the premium versions of both the PVC and Mohair Hooding ranges. In both of these materials, there are cheaper alternatives available which many other suppliers opt to use. Please see the FAQs for more information on this.

- John Skinners offer the widest range of colour options on the market – including all the correct original colour combinations, as well as many more custom shades.

- Worldwide material and colour samples service is available upon request, to ensure you get the look and finish your car deserves.

- Our kits are manufactured using the same methods and templates that we have used to great success for 40+ years. Rest assured, we know they fit!

- JSM has contributed to various notable Triumph restorations including TS01, and the much-publicised Triumph TR2 “Jabbeke“ MVC575 restoration project. We also worked closely with Mark Macy of Macy’s Garage (USA) on his wife’s TR4 – becoming the only Triumph TR to ever score the perfect 100-point score in the TRA Concours D’Elegance – back in 2018. Mark Macys own TR4 came in second place, at the same show – also with JSM trimmed fitted.

- Access to help and advice when it comes time to fit these weather equipment parts – we have been making and fitting these same parts for a long time – we know all the tricks, and we are more than happy to assist you or your trimmer should you get stuck.

| Unit of Sale | |

|---|---|

| Lead Time (*approx.) | |

| Number of Pieces | |

| Suitable Models | |

| Year of Manufacture | |

| Chassis Number Range | |

| Misc. Information | British Leyland, Carburettor, Coventry, Soft Top, Hardtop, Giovanni Michelotti, Independent Rear Suspension, Lucas Fuel Petrol Injection System, Standard Motors, Surrey Top, Triumph |

| Illustration Ref. | |

| Original Factory Part Number |

Please note that the colour names refer to internal John Skinner Ltd names, not necessarily the names Triumph originally used for these colours.

Due to industry-wide inconsistencies in production and record-keeping, it is widely accepted that the interpretation of original shades varies depending on who you ask. As a result, John Skinner Ltd offers multiple “original” shade options for you to make your final choice from. Below is a list of these accepted “original” colour choices that John Skinners can offer for your Triumph restoration project.

CUSTOM COLOURS/COMBINATIONS ALSO AVAILABLE

Note that we can also offer a variety of custom “non-original” shades if you prefer a more bespoke finish. For a full and complete list of options please view our Materials & Colours library.

SAMPLES/COLOUR CONFIRMATIONS

As part of the ordering process, we will arrange for samples to be sent for final confirmation – so browse and shop with complete peace of mind, knowing that we will guide you through step-by-step with all the information you require.

Please note that all materials are subject to colour shade differences between production batches. There may be subtle differences in colour shading between sample cuttings and final production material.

Due to the range of products we offer, and our worldwide customer base, we can only calculate an accurate shipping cost once Your Enquiry/Quote has been received by Jonathon. As there is no payment required at this stage – use our Quote Builder in full confidence, with zero commitment to purchase – and send us your Quotation request for your interior trim requirements; and we will get in touch directly with you with an updated Quote, which will include the shipment costs.

In the meantime, basic guideline shipping costs are outlined below.

(For all non-UK shipments – the final price per box depends on the size of the box – which is dictated by the items in your final selection)

UK: £10.50 – £30 per box

Europe & European Union: £20 – £150 per box

North America & Canada: £28.50 – £160 per box

Rest of World: £50.00 – £400 per box

Generally speaking, a complete car interior kit (Trim Panels, Carpets, Seat Covers, Boot/Trunk area, Soft Top Hoods etc) normally requires 2 x FULL Size Boxes, with some cars needing slightly less, and some slightly more.

Please note that these prices are exclusive of VAT (UK Customers ONLY) and any additional customs or handling charges that may be incurred during shipping. These prices are given as an approximation only.

For further information about shipping, and to learn more about how our shipping costs are calculated, please read our Shipping and Delivery guide.

🇪🇺 EU Shipments / Brexit 🇪🇺

As of January 2021, the UK is no longer part of the European Union (EU). As a result, several changes have been implemented which affects how EU based customers now purchase products from the UK.

It is not as problematic and complicated as people say. John Skinner Ltd sends hundreds of shipments to the EU; and rarely do we encounter any issues at all; and this is due to us working closely with our shipping agents to offer two choices that help to simplify the process for you.

You now have 2 Options you can choose from for shipping John Skinner products to the EU:

============

Option 1: Standard International Shipping

This is the ‘standard’ method of purchasing items from the UK, since the UK left the EU (‘Brexit’).

You will pay John Skinner Ltd for 1) the parts ordered, and 2) the shipping cost to ship from the UK to your address.

You will NOT be charged UK VAT (20% Tax). (Before Brexit, you would have been charged UK VAT @ 20%).

Once your parts ship, you will be contacted directly by our shipping agent (normally DHL), who will request payment from you for 1) Your Local Country Tax based on the value of the John Skinner Invoice, 2) a small admin fee (normally around €15). Once this is paid, your goods are released from customs and delivered to your address.

You will NOT be charged any Duties/Tariffs. All the parts we supply are made by John Skinner Ltd in the UK, and we provide all the correct paperwork & documentation and sign declarations to ensure that no Duties/Tariffs apply to our goods. (This is often the part that most people get confused by with Brexit – they assume that anything they buy from the UK incurs Duties/Tariff charges – our products are 0% Duty/Tariff rated).

Note that this shipping option is the default choice offered when Jonathon is raising your initial Quote; if you wish to discuss the second option (see below) – then just mention this to Jonathon once he has made direct contact with you about your enquiry.

============

Option 2: Prepaid Duties & Taxes *** VERY POPULAR OPTION ***

To simplify the purchasing process, you can choose our Prepaid Duties & Taxes option.

This process is becoming the most popular option for our EU customers as it makes everything very simple and straightforward, akin to how it was before the UK left the EU.

We will calculate & include all applicable import duties, taxes, and customs fees in your order total – and everything is paid up front to John Skinner Ltd.

Once the parts are ready and are shipped – you will NOT pay any additional costs, or have to do anything more – your order will be delivered to your address as normal. Our shipping agent (normally DHL) pays the Local Country Tax on behalf of John Skinner Ltd and they Invoice us for this later. This ensures that you won’t face any unexpected charges upon delivery, and your order will clear customs smoothly and quickly.

You can enjoy a more streamlined shopping experience with this option; like Brexit never even happened.

If you are interested in this option, please let Jonathon know once he has contacted you directly with your updated Quote via email; and he can update the Quote accordingly to reflect this choice.