Your Quote

Our panels are top-notch; precision cut, expertly trimmed and built from quality materials.

From the depth of our hardboard to the placement of our drill holes, we design and manufacture our panels with versatility and ease of fitment in mind.

In combination with our quality raw materials and HF / RF (high frequency / radio frequency) welding processes, our panel kits are made true to original specification, renowned worldwide for being the best in the industry.

Read more about the details behind our exceptional panel kits.

Original Trim Samples

We host an archive of original trim samples within our workshop. John acquired many of these samples when he started out in spare parts, and we have added to our collection over the years through various restoration projects we have been involved with. As John only took patterns from trim which he knew to originate from factory production lines, our library is a compendium of historical trim information and a reliable reference source for our trimmers.

Having this access to original trim panel work gives us the confidence to know that our kits are manufactured to original specification and made to fit. What’s more, each panel is cut with millimetre precision on our CNC machine which eliminates the risk of indiscrepancies arising from hand-cut panels.

Quality Sheet Materials

Hardboard

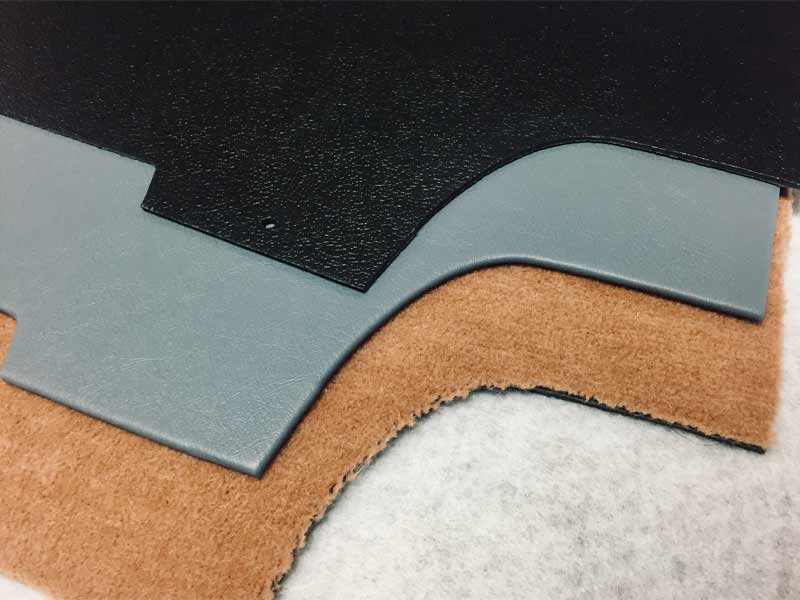

We manufacture the majority of our panel work using 2.55mm Hardboard which is sourced from a long established and specialised supplier – with over 100 years of experience in supplying marine and automative industries. Our Hardboard sheets are oil tempered to give the board increased moisture resistance and higher bending strength values. This allows us to maintain the correct thickness (2.55mm) for suitability of purpose on these cars, which tend to have very small tolerances for fitment. This material, with its particular 2.55mm thickness and oil tempered finish – is not something that can easily be sourced at your local DIY store – nor ordered online.

Other woods, such as birch or marine plywood, which are commonly used by other manufacturers in the industry – and happen to be original specification for some cars, particularly across the Austin Healey range – are significantly less suitable for purpose in these cars as they are thicker and do not have the capability to bend whilst maintaining the core strength. Even manufacturers who use Hardboard, often revert to the fairly commonly available 3mm thickness which is less suitable for purpose – that 0.45mm makes all the difference – and that’s how pedantic to detailing we are at JSM! We have used this same source and specification of Hardboard for our panels for over three decades and have found this material extremely suitable for purpose, as many of these interior panels require subtle bending when fitting into the cars to follow the curvatures of the bodywork. The unique oil tempering process of our Hardboard gives much improved water resistance properties compared with the hardboards and woods originally used on these cars during their original factory productions, which ultimately will help with the longevity of these panels.

Black Grain Board (also referred to as Millboard or Fibre Board)

Our Black Grain Board panels are strong and flexible in order to fit, shape and bend to bodywork curvature. This makes it an ideal material for Glove Boxes, UnderDash panels, Door Pockets and Boot / Trunk area panels that require flexibility when fitting. We also add crease lines to our Black Grain Board panels to allow for extreme bending in order to fit the panel to bodywork contours.

Black Grain Board is embossed with a grained surface finish to replicate the look of Vinyl or Leathercloth. We specifically use this material to enable certain areas to replicate the same finish as a trimmed standard Millboard panel. This is in-keeping with the originality of certain marques including the Triumph TR and Austin Healey Boot / Trunk areas, and it is worth noting that this effect is also in-line with many Concours judging guides for these areas of the car.

Depending on the model of car, and its trim specification, we can send our Black Grain Board panels trimmed or untrimmed. We will advise you on what would have been original specification for your car when you enquire with us, and we can also offer a custom finish if you are considering a non-original restoration.

Original Weld Tooling

We use our on-site High Frequency Welder to add original specification weld patterns to panel work. (Welding is the process of fusing together vinyl and foam under high heat and pressure to press weld lines and patterns into the surface of the vinyl – you can read more about our weld tooling here).

Welding was seen most commonly across Austin Healey 3000, Mark 3 BJ8 Quarter Panels, Triumph TR4 – TR6 Panel Kits and Jaguar Saloon Door Panels.

Early investment in weld tooling and machinery, particularly for Triumph TR’s, made John Skinner a recognised name in the industry for manufacturing replica panel kits that matched original detailing. As a result, we are one of the only companies in the world to have the original weld template designs for these cars and offer the welded finish as standard in our kits.

Traditionally welding was only applied to vinyl based panel work, but we are able to weld leather panel work for customers wishing to upgrade from original materials whilst retaining vinyl styling.

Considered Design

Our deep understanding of panel work – from how it’s fitted to what’s on show in the car – is reflected in how we design and cut our panels.

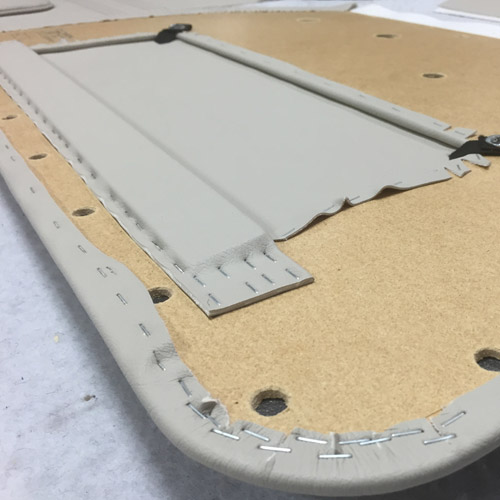

Fixing Holes

The majority of cars that we supply interior trim for originated from handbuilt factory production lines – a world apart from the digital production that we know today. As a result, these cars are often inconsistent from model to model, and are particularly inconsistent in the positioning of body work fixing holes.

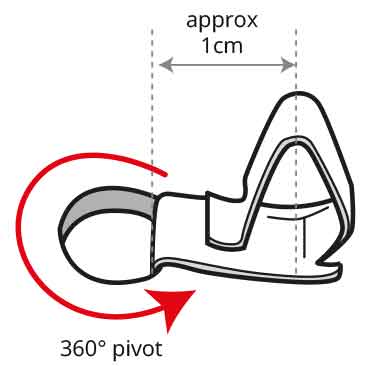

We have developed all our panels with this in mind, and have designed our fixing holes to allow for flexibility in fitting. Fixing holes act as a pivot point for Trim Clips, and provide the anchor from which to pivot the Trim Clip 360°.

The circular holes and the style of the fixing clip allow for a 360° rotation from fixing hole to fixing hole.

This allows for a large amount of flexibility when fitting the panel to the body work of the car. In some cases, you can change the position by upto 2.5cm (1”) between two adjacent fixing holes when matching up to the corresponding bodywork panel holes.

The trim clip fixing method gives us the confidence to know that we supply kits that fit, regardless of inconsistencies between models from original factory production lines.

Pilot Holes

We use pilot holes to help with positioning of trimmings and fixings. These small holes drilled through the panel give an indication for where elements such as door pulls, window winders, chrome work, armrests and door releases are located.

Precision Cut

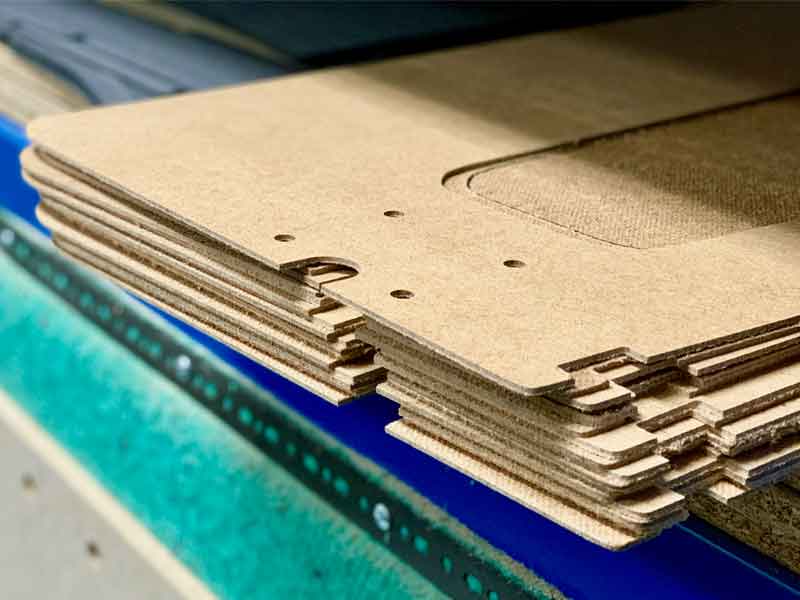

We cut all our Hardboard and Black Grain Board panels on our dedicated CNC machine. Using a pre-defined digital cutting file, we know that our blanks are cut with millimetre accuracy every time, eliminating production errors that could otherwise occur if cutting by hand. In addition to precision cutting, our CNC enables us to cut a high quantity of panels with speed, therefore increasing capacity on our production line.

A few more details that really make us proud of our Panel Kits…

Professional Finish

Our panels are expertly finished and made to look as good on the back as they do to the front.

Our Skilled Trimmers

Our trimmers really are professionals in their field. With a trained eye and exceptional skill set, they are true perfectionists.

Stamp of Approval

Each panel made in our workshop is stamped proudly by our trimmers with the John Skinner mark of approval.

- Categories: Trimming and Fitting