We offer leather skiving as standard as part of our trim kits. But what does skiving really mean and what benefits does it bring to your classic car restoration?

Here, we take a closer look at why we offer this service on our leather trim kits.

Some areas of classic car restoration are well-known to be difficult to trim. Centre Consoles, Dash Facias and Door Tops fall into this category. Given their location within the car, there’s little room for error and no place to ‘hide’ unsightly tucks and lumps.

From our workshop, we wanted to do something that would help resolve this issue and enable our customers to achieve a smooth and precise trimmed finish in these areas. We knew that the problem largely came from working with leather that was too thick to trim round corners and curves, so we invested in a leather skiving machine.

What is a leather skiving machine?

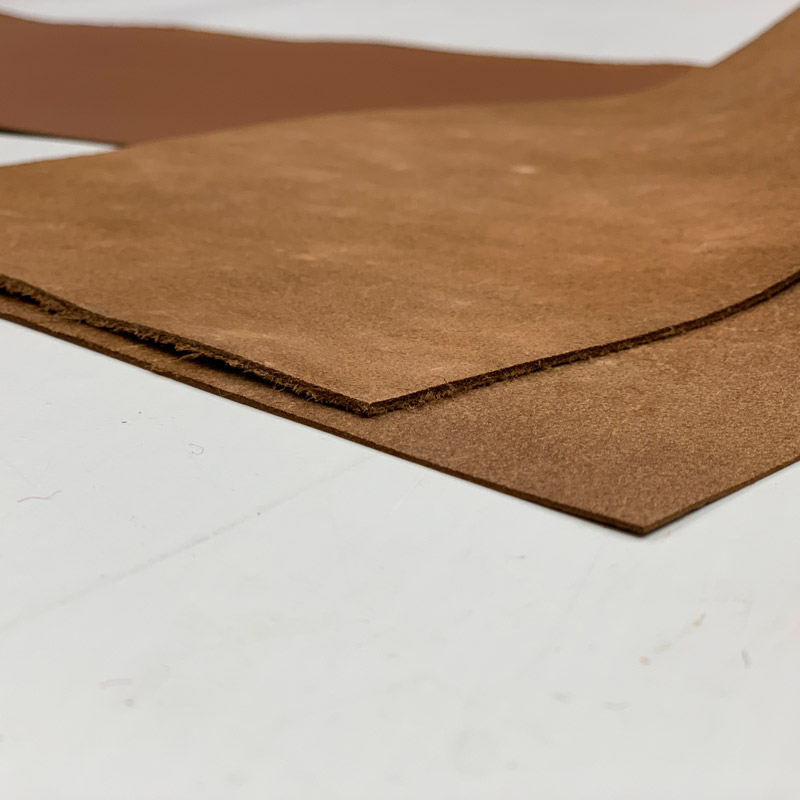

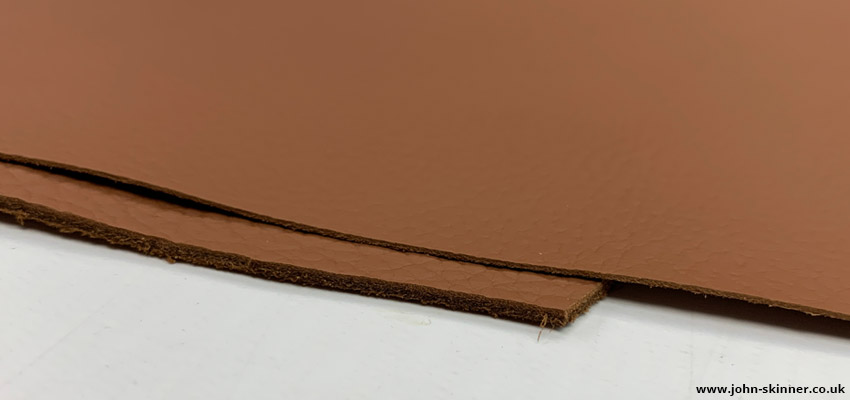

A leather skiving machine works by ‘shaving’ off the back of the leather to reduce its overall thickness. Although the leather is thinner, it remains strong and maintains its original surface finish.

Most importantly, the thinner leather then becomes much more pliable and flexible to work with, enabling the trimmer to ease the leather round corners and curvature with a smooth finish.

What parts of a trim kit can be skived?

As standard, we generally skive Centre Consoles, Dash Areas and Door Tops. We know from experience that these areas benefit from skiving, and using a thinner leather for trimming these parts gives a better overall finish. We are confident that using skived leather in these areas does not compromise the quality, finish and endurance of the leather.

At your enquiry with us, we will discuss which areas of your trim kit will be suitable for leather skiving, as these can vary from model to model.

It is worth noting that we would never skive leather for ‘high use’ areas such as Door Pulls or Gear Lever Gaitors as the natural thickness of leather is well suited to use in these parts.

Is there an additional charge for leather skiving?

No. We offer leather skiving as standard across all our trim kits. There is no additional charge for this service.

We are committed to serving our customers with the highest quality kits on the market, and by offering this service at no additional charge, we are ensuring that all our customers can enjoy and reap the benefits of working with skived leather.

In addition to our Leather Skiving Machine, we have a variety of other machinery on-site in our workshop that helps us craft our interior trim restoration kits. Read more about these in Inside Our Workshop: Cutting

- Categories: Colours and Materials