The successor to the TR3, dubbed the TR3A, commenced production during 1957, and continued through 1958, 1959, 1960, 1961, ending in 1962, with a short batch run of the TR3B model. During this time a total of 58,309 TR3A cars were produced, with 3,334 TR3B models.

John Skinner Ltd has produced awarding winning interior trim and upholstery kits for over four decades, including contributions to the Jabbeke MVC575 restoration, as well as the TS01 and TS02 cars – meaning that we have been involved in arguably three most important restorations of the TR era. We also had the honour of working on the restoration of the TR3A used in Federico Fellini’s lauded 1960 Italian film “La Dolce Vita” – winner of the coveted Palme d’Or.

Start Your Restoration With Us

Use our Enquiry Form or send us an E-Mail to tell us about your restoration requirements.

To view our Parts & Prices – Download our Catalogues or visit our Build-a-Quote system.

A Restorer's Guide to the TR3A & TR3B

We have created this OEM guide based on the knowledge we have acquired through well informed parts books and our own extensive records of original parts and photos, in addition to over 40 years experience in manufacturing trim restoration kits. However, we would always advise that due to inconsistent methods on the production lines and notoriously vague historical record keeping, that you take OEM specifications with the proverbial “pinch of salt.”

This guide gives a basic overview of how the cars would have originally left the factory, and may differ slightly to how we now manufacture the kits due to changes and advancements in modern day production methods and new – and more suitable – material developments. You can find detailed information on how we supply all our parts on the individual products pages within Build a Quote.

To help you best understand this guide, you may find our Glossary tabs useful where we list and explain common terminology used across interior trim.

Please note that there were production inconsistencies during this period, so colours should be chosen on individual basis.

| PAINT COLOUR | INTERIOR TRIM COLOUR OPTIONS | SOFT TOP / SIDESCREEN OPTIONS |

|---|---|---|

| Black | Red, Blue (“Midnight Blue”), Black, Silverstone Grey, Targo Purple | White, Fawn, Black |

| Signal Red | Red, Black, Silverstone Grey | White, Black |

| British Racing Green (BRG) | Red, Silverstone Grey, Targo Purple | White, Fawn, Black |

| Pale Yellow | Black, Silverstone Grey, Targo Purple, Red | White, Black |

| Powder Blue | Blue (“Midnight Blue”), Black | White, Black |

| Sebring White (Spa White) | Red, Blue (“Midnight Blue”), Black, Silverstone Grey, Targo Purple | White, Black |

| Silverstone Grey | Silverstone Grey, Targo Purple, Red | Black |

| Pale White | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

| Pearl Grey | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

| Winchester Blue | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

| Sunset Red | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

| Apple Green | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

| Primrose Yellow | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

| Beige | Any approved trim colour. Approved colours appear to have been: Red, Blue, Black, Beige, Grey, Targo Purple & Silverstone Grey | Any approved colour acceptable – Black, Beige or White as scheduled by sales department |

Information from: Piggott, B. (1991) Original Trimph TR – The Restorer’s Guide to TR2, TR3, TR3a, TR4, TR4A, TR5, TR250, TR6, Bideford: Bay View Books Ltd.

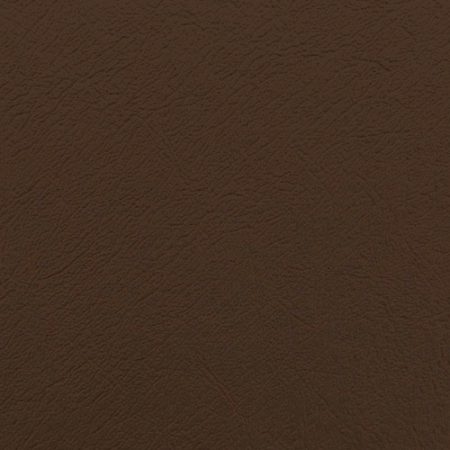

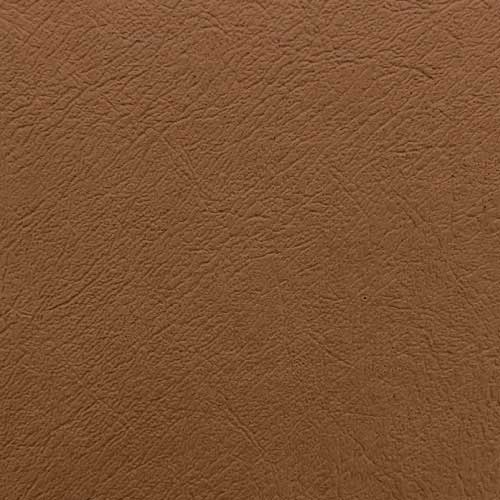

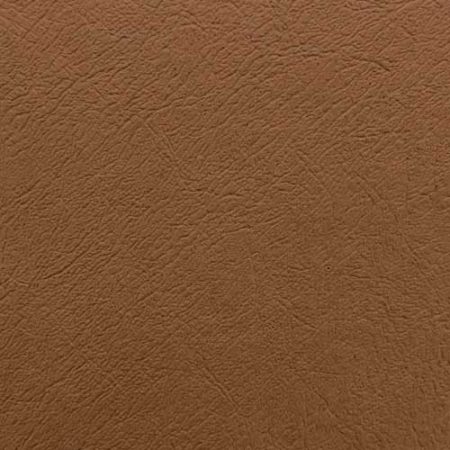

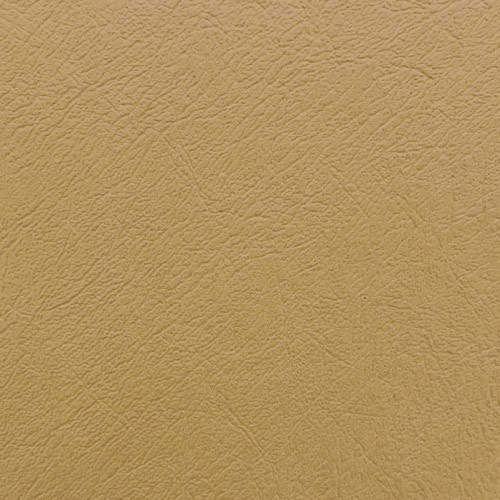

Triumph TR3A / TR3B Original Colours supplied by John Skinner Ltd

It is widely accepted that the interpretation of original shades varies depending on who you ask – and may well have varied from the original factory production line. As a result, John Skinner Ltd offers multiple shade options for each original colour.

Colour names refer to internal John Skinner Ltd colour names, not necessarily the names Triumph originally used for these colours.

We can also offer non-original custom colour schemes if you so desire. Please see our online shop for more details.

As part of the quotation/ordering process, we will arrange for samples to be sent for final confirmation – so browse and shop with complete peace of mind, knowing that we will guide you through step-by-step with all the information you require.

A note on Piping/Beading

Triumph TR3A/TR3B models originally featured White Piping on the majority of cars that left the factory production line, with a few recorded instances of Piping matching the main trim colour.

We can also offer the largest range of non-standard “bespoke” colours schemes for those looking for a more customised finish.

Interior Trim Panels

Unofficially dubbed the TR3″A”, September 1957 saw some fairly major interior trim and upholstery modifications in the TR3A from its TR2/TR3 predecessors and the production run delivered 58,309 TR3A models and 3,334 TR3B models to the market.

Panels

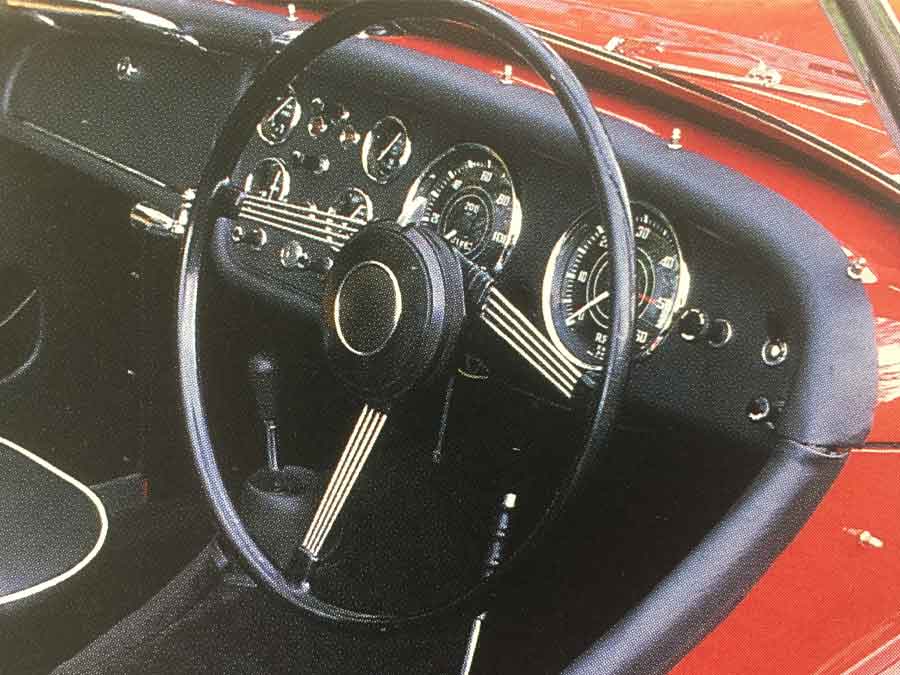

The interior trim panels consisted of the main Door Panel Casings, Door “Map” Pockets, Quarter B Post Panels and Rear Bulkhead Panel. These were all manufactured in Millboard/Fibreboard material, barring the Rear Bulkhead panel which was made from Hardboard (or Hardboard/Metal combination for some models). The Rear Bulkhead Panel featured a horizontal and vertical line pattern which, for the most part, was embossed into the material with a few exceptions of the early TR3A models where the effect was achieved through sewn pleats. In addition to these panels, the TR3A models also had metal (aluminium/steel) cappings for the Dashboard Facia Panel, Dash Top Scuttle Crashroll, Door Tops, Quarter Elbow Cappings (“Dog Legs”) and the Tonneau Capping around the rear cockpit area of the car. The majority of these panels were fitted to the car using chrome self tapping screws and washers.

Loose upholstery trim

There were various pieces of upholstery to cover the bodywork of the car. These consisted of the Wheel Arch / Wheel-Well areas directly in between the Quarter Panels and Bulkhead Panel in addition to the sewn Door Pull Lanyard Sleeve Covers situated on the Door Panels (which had now been updated to house a ‘chain’ mechanism for increase their longevity). The Door Pockets were a flocked material, loosely matching the main interior trim colour, with an open top to allow for the updated Door Pull Lanyard Cord, which was now attached to the inside section of the Door Pocket/Panel. Draught excluders were still required at the front and rear edges of the main door opening, but Triumph updated these to a velour-like ‘moquette’ furflex material, moving away from the somewhat basic folded and stapled Vynide materials used on the TR2/TR3 models.

Original materials

The TR3A and TR3B models left the factory with the panels upholstered in Vynide (Leathercloth). Commonly these days, this material is superseded with Vinyl (Ambla), although Leathercloth (Vynide) is still available if requested (colour dependent). Very few cars, if any, would have left with Leather panels – and if they did, this would have been a special order item. At this point it is worth noting that when “Leather” is mentioned on the heritage certificates, this is often only referring to the Seats and some of the Cappings around the cockpit of the car (more on this below and under the Seat Kits tab).

The Cappings were either all Vynide or a mix of this Vynide and Leather, depending on the era of the car. It appears that most of the early cars left with a singular Vynide material, whereas the later cars introduced Leather for five of the high wear cappings. The Dashboard Facia Panel was updated to a black crinkle paint for the TR3A/B models, moving away from the earlier material covered panel. The three rear Tonneau Capping were also always Vynide. It was the Dash Top Scuttle Capping, the two Door Tops and the two Quarter Elbow Cappings that subbed out Vynide for Leather on some cars. This is often referred to as the 5pc Leather Capping Kit, or the 7pc Leather Capping Kit if you also include the Leather Door Pull Sleeves for covering the chain-cord which was introduced for the majority of the TR3A/TR3B models. If heritage certificates mention ‘Leather,’ then this would almost certainly be referring to these 7 pieces, in addition to some elements of the Seats.

The Vynide used featured a fine grain running through the face of the material, which was continued on all TR models up until the 1973 era TR6.

Piping

The Door, Quarter and Bulkhead Casing Panels featured white piping/beading – not only to improve aesthetics, but also to hide gaps between the panels and bodywork!

Seat Kits

Front Seats

One of the main overhauls from the TR3 to the TR3A was the front seats – which became narrower and more “egg” shaped whilst still maintaining a subtle bucket shape to the backrest. The seat framework was also updated accordingly.

At this stage it is crucial to mention that many after-market suppliers fail to distinguish the major differences between the TR2/TR3 Seat Frame design, and the later TR3A/B design. Whether this is down to the confusion of the terminology of TR3 vs TR3“A” – or a general lack of understanding of the actual Seat design changes – we have witnessed many examples of customers being mis-sold Seat Frames and then not understanding why the Seat Covers do not fit correctly (this is not simply a case of poor fitment – you simply will not get them to fit to the backrest frame at all!).

Original materials

The covers themselves were mostly supplied in a Leathercloth (Vynide) which is often confused with and substituted for Vinyl (Ambla). Some cars would have left the factory with Leather seat covers; albeit these would have most likely only been supplied with Leather to the facings of the seat (the elements of the seat covers which touch your body as you sit in the seat), with Leathercloth still used to the seat backs and surrounds. This configuration is commonly referred to as “LeatherFaced” and should not be confused with Full Leather.

Front seat design

The construction of the seat skins was redesigned completely for the TR3A and TR3B models with a horizontal pleat squab and cushion pattern design. The piping on this updated seat assembly focussed mostly on the outer contours of the cover, as the horseshoe design of its predecessors was abandoned. Instead, two rows of piping were used on the outer circumference of the backrest squab cover, and a single row of beading used on the outside edge of the cushion base cover. These outer pipings were originally White for the large majority of the cars that left the production line. There was a small horizontal piping section on the cushion front panel section – which was always self-coloured to match the main trim colour. The backrest pleats were sewn in using millboard on the underside of the foam to allow for the correct curvature of the seat cover to take formation.

Seat hardware / fitment

As the design of both the Seat Frames and Covers changed from the earlier TR2/TR3 cars, the associated Seat Hardware was also updated. Essentially they used the same parts – Tacking Strips, Coil Springs and a Padding Kit – all three differed in design to the earlier versions.

With that being said the concept was the same – the backrest covers are fitted to the seat frames using Tacking Strips which are riveted to the seat frames in specific areas. Tacks are then used to help attach the material to the framework. This allows for flexibility when trimming by avoiding a more ‘permanent’ fixing and enabling tacks to be removed and re-sited according to the tension required during fitment.

Cushion covers are fitted to the coil spring units using hog rings.

Seat paddings were originally basic fibre/horse hair material for the inside of the Backrest Frame and the top of the Cushion Base (which sits on top of the spring unit). The backrest backs used a thin felt material as a basic padding.

Rear Seats

The occasional Rear Seat was a more frequent sight in a TR3A in comparison to the TR2s and TR3s, but it still wasn’t a standard element of the interior trim. For those cars that did include it, it was made up of a cushion base unit (no backrest), with a horizontal pleats, white piping around the outside edge and a self-coloured piping to the horizontal inside seam, very much reflecting the design of the front seats. Across the TR3A/TR3B production run, there was a change to the rear seat design to reflect an update to the Rear Deck Shelf Area that initially was sloped but was made flat around TS60,000. Any cars up to this point would have had a ‘curved’ front edge to the rear seat, whereas those models post TS60k and all TR3B models would have had a ‘square’ front edge. The earlier design for the “sloped” rear shelf section required a couple of metal up-stand brackets for fitment in the car, whereas the later “flat” rear shelf version simply sat on top of the carpeted rear shelf area and was fixed down in place to secure it.

Carpets & Flooring

The carpets in the main cockpit area of the car included pieces for the Main Footwell and Rear Floor Pans, the Engine Firewall Bulkheads, the “A” Post Pillar Bulkhead, and the Gearbox and Transmission/Propshaft/Driveshaft covers, in addition to the Rear Heelboard/Bulkhead Shelf behind the seats. Unlike the earlier TR2/TR3 models, the TR3A cars were updated to a one-piece design for the main Gearbox/Clutch Housing section.

Original materials

Records suggest that the Triumph TR3A models left the production line with Wool carpets, as well as Nylon depending on the era of manufacture. Although notes like this should always be taken with a pinch of salt – our archive states that cars up to around TS35,350 were always fitted with Wool carpets, with cars after this point sometimes leaving with Wool carpets, and sometimes with Nylon (“loop pile”) carpet. As per the earlier TR models, the carpet pieces featured a Vynide (Leathercloth) binding on the edges, although not all edges of every piece were bound. A rubber ribbed Heel Pad was situated on the Driver’s side Front Floor Footwell carpet, as well as a small “D” shaped Heel Pad on the Driver’s side A Post Bulkhead Panel, and the Driver’s side inside edge of the main Gearbox Cover. The Gearbox Cover included a pre-cut hole with sewn surround opening for the Gear Lever “Boot” Gaitor. The sloping Rear Shelf Bulkhead area was trimmed onto a Millboard panel, which was superseded by a non-trimmed carpet piece for the later “flat” rear shelf sectioned cars (Post TS60k).

Short note on Underfelt

Carpet Kits were fitted on top of a layer of Underfelt, providing basic heat and sound insulation with an additional layer of comfort underfoot. Typically this was a natural jute felt of around 6mm to 8mm in thickness. Not all the carpet sections were fitted with corresponding felts underneath them.

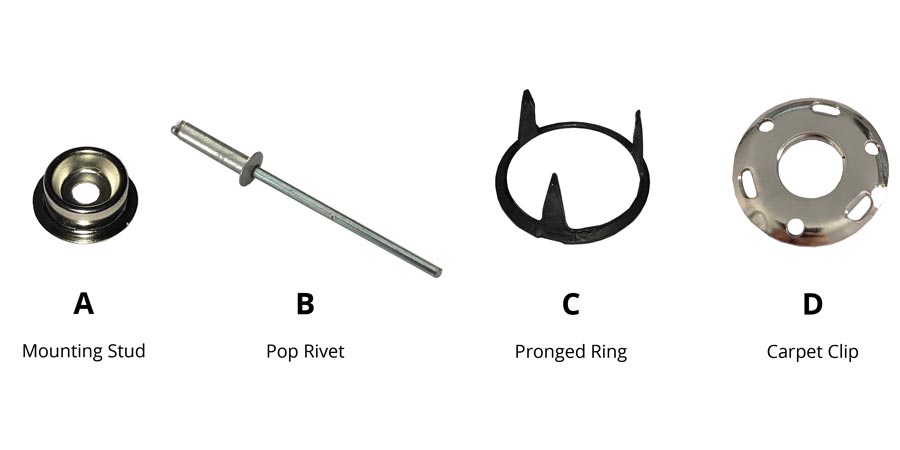

Fixings

Four different types of Fixings were used to keep the carpets in place and all these fixings are still available today.

Mounting Studs (A) are secured to the bodywork floor pans using Pop Rivets (B). Then the Pronged Rings (C) are pierced through the carpet pieces in various areas and secured using the corresponding chrome Carpet Clip (D) to the back of the carpet. This allows the Mounting Stud (A) and the Carpet Clip (D) to clip into one another thus securing the carpet parts in place. The positions of these fixings is a subject of much debate – although you should often be guided by the pilot holes found in the bodywork of the chassis itself.

Boot / Trunk

The Boot Area (referred to as the “Trunk” by our American cousins) remained unchanged throughout the production period ranging from 1953 to 1962, which saw over 80,000 Triumph TR2, TR3, and TR3A/B models leaving the production line in Coventry. The floor of the Boot Trunk Area was originally fitted with a mat, most commonly supplied in black with the exception of the very first TR2s where a ‘coloured’ alternative was an option. This mat cover was supplied in carpet for most models, with records suggesting that some late TR3A and TR3B models switched to Hardura (a felt-backed PVC material). The mat was edged in Leathercloth (Vynide) along three of the four edges, with a ‘T’ slit opening in the centre of the longest edge for the boot latch mechanism cable.

The vertical back of the Boot Trunk Area was originally fitted with a Millboard Panel to cover the front bulkhead of the Boot / Trunk area directly behind the main fuel tank. The large majority of TR2 to TR3A/B models left this part supplied in a black surface grain finish – imitating the look of leather – but a few early TR2 models would have left with this panel in the same colour as the bodywork paint.

The left and right side panels of the Boot Trunk Area were left exposed to show the painted bodywork. (It is worth noting here that John Skinner can supply Boot Trunk Side Covers for this area of the car which is often overlooked but can benefit from some extra attention in trimming. These were templated to cover the curved Wheel Arch sections and the flat bodywork section just behind them).

Weather Equipment

Convertible Soft Top Hood

To the untrained eye, you may be mistaken in thinking that the TR2 all the way to the TR3B models shared the same Soft Top Convertible Hood. The reason being that the overall size and general appearance remained the same throughout this nine-year production run. However, there were actually three different variants spanning these models.

According to our records, approximately half of the TR2 models (around 4400) were fitted with a singular window in the rear – which was relatively small when compared to the later variants. This was then switched in favour of a larger centre window accompanied by the addition of two side “quarter panel” windows – presumably to aid with clearer vision when looking rearward! This same Three-Window design was used throughout the TR3 production run, and carried on into the TR3″A” era briefly before another subtle update was made to the Hood at around chassis number TS28k. Whilst all earlier cars had been fitted with a Hood that had seams running the length of the Hood down the left and right outer edges, early on in the building of the TR3As these seams were removed, instead creating a convertible top made from one large piece of material, with no joining seams. This version continued until the end of the TR3A/TR3B production run. It is worth noting that the fixings used to attach this cover to the car also changed during the 9 years they were leaving the factory line, so it is always best to double-check which style you have on your individual car at the point of ordering.

The majority of Triumph TRs left the factory with PVC Hooding – this is effectively a PVC vinyl plastic material with a waterproof membrane which features a grain on the surface of the material to imitate vinyl/leather. The actual material used was Everflex (known as “British Everflex”) – which was an ICI trade name for PVC Hooding (think “sticky tape” and “sellotape”!). Some special-order models may have left with Deluxe Mohair Canvas (also referred to, albeit not exactly the same as Stayfast/Twilfast etc – see Glossary for more details). The clear plastic window(s) at the back was made of Vybak plastic.

Hood Frame “Envelope” Cover

Triumph was one of the first sports car manufacturers to commonly use the Hood Frame Cover on their cars as a stowage cover for the framework of the convertible top. Sometimes referred to as “Hoodstick Covers” or “Top Frame Covers” or “Boot Envelope Covers” – this is the pre-sewn material cover that is used to hide away and cover up the folded down metal framework of the Soft Top Hood. On the early TR models, the Convertible Hood cover had to be removed from the frame prior to folding the frame away behind the seats and covering over using this Hood Frame Cover.

During the period from 1953 to 1962, Triumph manufactured two designs for the Hood Frame Cover, changing production during the TR3A era around chassis number TS41k. The switch was very subtle and is related to the corner tails around the B Post area of the car. Note John Skinners is one of the only companies to acknowledge this small update and have both patterns.

As with the other weather equipment items, the fixings changed at some point during the production of these parts too – with “baby” tenax fixings initially being used, before being updated to the standard size tenax fasteners, and again updated to Lift-The-Dot fasteners further into the production run.

Hood Frame Covers would have been made from PVC Hooding, and the colour would have always matched the colour of the Convertible Soft Top Hood and Tonneau covers when leaving the original factory production line.

It is worth noting that the Hood Frame Cover is only ever on show alongside the interior trim (and not any other Weather Equipment) and has no requirement to be waterproof. As a result, a popular option is to deviate from originality and have the Hood Frame Cover made from Vinyl / Leather to match the interior trim.

Tonneau Cover

The Tonneau was a standard option for these cars leaving the factory. Designed as a convenient option for quickly covering the interior of the car – either completely, or leaving half open so that the car can still be driven – these covers became a staple item for many sports cars of this era. A pocket is located on the Driver’s Side to allow the steering wheel to be covered when the cover is fully in use and the slightly off-centre zipper offers a larger opening on the Driver’s Side for when using the cover half-open.

As with the cover for the Convertible Soft Top Hood – the Tonneau Cover remained largely unchanged in terms of basic appearance and size through the nine-year production of the TR2, TR3, and TR3A/B models. The only major change was in the length of the Tonneau at the front, with the early TR2 models – the first 5000 or so that left the production line (see our Product Page/Handbook section for exact chassis number changes) – being slightly longer than the standard size adopted for all other remaining TR2-3B models. (John Skinners is one of the only companies to recognise this difference with the ability to cater for both lengths). The reason behind this longer length is based on the original mounting positions of the male fixings on the bodywork of the car; for the early TR2 models these fixings were further forward in line with the rearview mirror mounting bracket. Not long into the initial production, this was switched to the far more commonly seen “standard” version where these male fixing points were located in the actual Dash Top Scuttle Capping metalwork. Barring this detail, all other aspects of the Tonneau covers between the TR2 to TR3B models remained the same.

Tonneau Covers were most commonly made from PVC Hooding. Some special-order models may have left with Deluxe Mohair Canvas.

Useful advice – please be under no illusions, the Weather Equipment elements (Soft Top Hood and Tonneau Covers) are tricky to fit, even for an experienced trimmer. We strongly urge you and your professional trimmer to contact us for directions on the best methods for fitting these items, as sometimes some steps are irreversible. These parts are not meant to be easy to fit – that’s why when they are done correctly, the material is so tightly pulled and taut as a drum. Don’t leave this to chance, ensure you fully understand the process of fitting before you start.

Glossary of Materials

Armacord – a coloured grained PVC material with a natural jute felt backing and ribbed surface finish. Very similar to Hardura in quality but the ribbed effect was a finish used specifically to Austin Healey models across a combination of Rear Floor, Boot Trunk and Rear Deck areas depending on the model specification. Also seen on Jaguar C Type Gearbox Tunnels.

Beading – see ‘Piping.’

Binding / Edging – a strip of Leathercloth that is fed through a binding machine and secured around the edge of a carpet. Generally only applied to edges of carpets that are exposed when fitted. Leathercloth is a sturdy yet nimble material that gives a neat and durable edge to carpets, enabling them to lay flat when fitted. (Please note, Vinyl binding – although available in a wider colour choice – is thicker than Leathercloth which results in a bulky appearance. It can also catch and snag easily, and wrinkles around corners when sewing. For these reasons, we never use Vinyl to bind our carpet edges at John Skinners).

Carpet: Karvel – Karvel carpet is a utilitarian floor covering with a tough ribbed surface structure and a woven hessian backing. Seen most commonly throughout Austin Healey and MGA interiors.

Carpet: Nylon – Nylon carpet is a man-made material constructed from polypropylene fibres glued to a flexible rubber backing. Ideal for budget restorations, or for areas of the car that are rarely on show e.g. Boot / Trunk areas. Avoid this choice for the main cockpit cabins if possible – Wool is always preferable and far superior.

Carpet: Wool – Wool carpet is spun from wool yarn and glued to a flexible rubber backing. The wool fibres provide a thick, springy and dense pile that doesn’t spread when fitted over bodywork curvature. Luxurious to the touch. Something about superior in quality, finish/touch etc etc – this should be the choice for most restorations

Carpet: Wilton Wool – used for immensely luxurious, spacious and often chauffeur-driven saloon cars e.g. Rolls Royce and Bentley. Very densely packed, fluffy pile – akin to living room carpets. Not suitable for sports cars where its quality and feel looks out of place.

Carpet: Loop Pile – a carpet where fibres are ‘looped’ and left uncut to create a flat and durable carpet surface. Most commonly used on Triumph TR4s. Please note that Loop Pile carpet is not supplied by John Skinners.

Edging – see ‘Binding.’

Fibreboard – see ‘Millboard.’

Furflex (Tac-On & Snap-On) – with a similar velvet-like touch to Moquette, Furflex is the name given to a very short pile, high quality wool mix material wrapped around a rubber tube with a flanged edge. Used most commonly for trimming around door edges for the purposes of a draught excluder.

Hardboard – a versatile wood based material with one side having a very smooth finish and the other a heavily grained finish. It was used very extensively for Trim Panels and gradually replaced Millboard. ‘Motor Grade’ Hardboard is around 2.5mm thick – thinner than the more readily available 3.00mm – that 0.5mm makes all the difference – which allows for doors to close fully against draught excluders and be fitted to the bodywork of the car with the use of Trim Clips which are designed specifically for use with the original 2.5mm thick board.

Hardura – a coloured grained PVC material with a natural jute felt backing. Most commonly used to trim Boot Trunk areas – particularly across the Jaguar range – and was also used for flooring and other interior parts.

Headlining: Union Cloth – a woven material made from wool/other fibre mix (around 80% wool content, 20% cotton). Ideal for lining the interior roof of the car – most commonly Jaguar XK and MK2 (Saloon) models. Available in 2 colours; beige and grey to complement all interior colours. 200cm wide.

Headlining: “West of England” Wool Cloth – a woven material made from 100% wool fibres ideal for lining the interior roof of the car – most commonly Jaguar Saloon, Sedan and XK-E models. Available in 3 colours; beige, green and grey to complement all interior colours. If trimming a roof from its bare bodywork, opt for pre-bonded foam backed wool cloth to avoid having to twice glue and trim the headlining area; first to apply a foam base, then to glue and trim the headlining onto the foam. 150cm wide.

Hidem – made from Leathercloth or Hooding, Hidem is a type of banding – around 16mm wide – with a central seam running through it that can be used to hide unsightly tacks and staples across trimming work. Seen, for example, around the base of the backrest on Austin Healey BN1-BN4 Front Seats; and commonly seen on the header rails of soft top convertible Hoods.

Hooding: Deluxe Mohair Canvas – a woven twill waterproof canvas material with a dense rubber membrane encased between its twill surface and a textured dobby backing. A premium material seen most commonly on Soft Top Convertible Hoods for the Jaguar XK and some E-Type models. With minimal shrinkage qualities, Deluxe Mohair Canvas is exceptionally durable. Can also be referred to / known as – DMC, Canvas, Haartz®, Sonnenland®,, German Canvas or Dobby Cloth.

DMC is the superior canvas hooding product; more so than the commonly seen SMC (Standard Mohair Canvas) products on the market, which can also be referred to / known as – Stayfast®, Twillfast®.

Hooding: PVC – a waterproof plastic coated material with a knitted cotton backing. Heavily grained surface finish. ‘Everflex’ is the ICI trade name for PVC hooding. Can also be referred to as – British Everflex, Vinyl Hooding or Crush Grain Vinyl.

Leather – a natural product derived from animal skins with marks, blemishes and scratches an inherent part of the materials’ surface and character. Modern day processes – such as mechanical graining and dyeing techniques – help hide imperfections to maximise use of the hide, reduce production waste and make leather products accessible to the wider market. Whilst Vaumol™ natural grain leather would have been original for these cars, our Grained, Smooth and Antiqued Leathers offer a more than suitable alternative in keeping with originality – you can read more about these here.

Leathercloth / Vynide – both names refer to the same material; a coloured and lightly grained PVC material with a thin woven cotton backing and no stretch. Leathercloth / Vynide replaced Rexine in the marketplace. ‘Vynide’ was the ICI trade name for this material. Used for Trim Panels, Piping & Binding. The choice for restorers looking to return their interior to truly original specification. Available in a select range of colours.

Millboard – a flexible and tough cardboard like material with a grained finish to its surface. Used for Trim Panels & Boot Trunk Areas. Can be creased to allow for bending around bodywork fixtures such as Petrol Filler Pipes. Can also be referred to as ‘Fibreboard.’

Moquette – a short pile, high quality wool mix material with a velvet-like touch. Used for various trim items across the Jaguar range such as Seat Backs, Wheel Arch Covers and Trim Panels. Available in a variety of colours.

Piping – a flexible core encased in either Leathercloth or Vinyl and finished with a flanged edge. Sewn around seat edges and pleated panels, and either sewn or stapled to some interior panels such as Wheel Arch Covers or Door Panels. (Please note, although Vinyl piping available in a wider colour choice than its Leathercloth counterpart, it is thicker than Leathercloth which results in a bulkier appearance. It can also catch and snag easily, and wrinkles around corners when sewing. We would always recommend to use Leathercloth piping where possible, unless you feel particularly limited by colour choice within the Leathercloth range).

Piping: Chrome (as seen on Austin Healey BJ8 Front & Rear Seats) – a silver and black twisted yarn core encased in bendy plastic with a flanged edge to create a ‘chrome’ / metallic effect piping. Original for Austin Healey BJ8 Vinyl Front & Rear Seats. Often referred to incorrectly as ‘gold’ piping (the result of the original chrome piping yellowing through age and sunlight exposure).

Piping: Plastic (as seen on Triumph TR4-TR6 Panels & Seats) – a 3mm moulded plastic piping only available in Black or White. Originally used for Triumph TR4-TR6 Interior Panels & Seat Kits. No longer used by John Skinner for Seat Kits as it does not provide the flexibility required for good seat structure. John Skinner would only use this plastic piping on trimmed panels if customers are not ordering seats to match. Where customers are ordering both Interior Panels & a Seat Kit, Leathercloth piping is used in place of the original plastic piping.

Rexine – a coloured and lightly grained plastic material with a thin woven cotton backing and no stretch. Rexine was an early type of Leathercloth, but thinner and of a similar quality to book-binding material. Used across Trim Panels, Piping & Binding. It is no longer available on the market and was gradually superseded by Leathercloth / Vynide.

Underfelt – a natural material made from compressed jute felt fibres to offer heat and sound resistance properties. Anti-scuff finish to face. Flexible, durable and essential for flooring restorations to ensure carpet kits fit correctly. Place directly onto the bodywork floor of the car prior to fitting carpets on top. Can be used in conjunction with modern-day heat and soundproofing materials such as Dynamat®.

Vaumol™ – a leather finishing process developed in-house by Connolly Leather to celebrate the natural and individual characteristics, patina and aroma of each hide. The leather is vegetable tanned and surfaced dyed and left with its natural grain to the surface which is enhanced through the Vaumol™ finish. ‘Luxan’ hides are further enhanced with a secondary colour application.

Vinyl / Ambla – both names refer to the same material; a coloured grained PVC with a thick knitted cotton backing allowing for good stretch qualities. Its knitted backing makes it thicker than Leathercloth / Vynide. ‘Ambla’ was the ICI trade name for this material. It was introduced to the market in the early 1960’s and was used widely across Trim Panels & Seats from this period onwards, quickly replacing its Leathercloth alternative. Favoured by today’s restorers due to its more flexible nature and wider colour range availability, it is quite common to see Vinyl used as a substitute for Leathercloth.

(Note that for carpet edging and seat piping, we would always recommend using Leathercloth. It is thinner than Vinyl, making it more suitable for sewing round corners and curves without wrinkling or adding bulk).

Our Customers' Cars

…and people say that “pre-manufactured upholstery kits will never fit“.

Our customers beg to differ; and we have the photos to prove it – thanks to thousands of loyal clients from all over the world keeping us informed about their restorations.

See for yourself…and remember – it is our accurate pattern making (all from original templates & donor cars) and in-depth knowledge of these cars, as well as our precise, modern-day manufacturing processes that enable us to produce world class, award winning kits rarely rivalled by others.

Whether you’re a professional trimmer or an amateur enthusiast – a John Skinner Ltd kit is the best way to kick-start your interior trim restoration.

From our Handbook

Start building your Quotation

Build-a-Quote

Use Build-a-Quote to create your own quotation, specific to your car & restoration requirements.

Unsure on what parts and colours you need? Add all the options you’re considering and we’ll be back in touch to discuss further. For more information on our Build-a-Quote system, please see our FAQs.